Work Packages

The Work Packages (WP) covered the following areas of the wood-supply-chain:

* demands of main industrial sectors in “WP 3000 Meeting of Industrial Requirements”;

* forest resource inventory in “WP 4000 Integrated Forest Inventory Design for Optimised Quality and Quantity Assessment of Wood Resources”;

* harvest and transport in “WP 5000 Novel Harvesting and Logistic Concepts for Integration of Forestry with Industry”;

* efficient mill production based on advanced information in “WP 6000 Flexible and Customer Adapted Mill Production”;

* combining the previous WPs in a novel logistic system using IT components “WP 7000 Communication Infrastructure for the Support of Increased Wood Supply Efficiency”; and

* demonstration of the concept on Use Cases in Germany, France, Sweden and Poland in “WP 8000 Implementation and Demonstration of the FlexWood Concept”.

In addition, there were work packages in Management (WP 1000) and Dissemination (WP 2000).

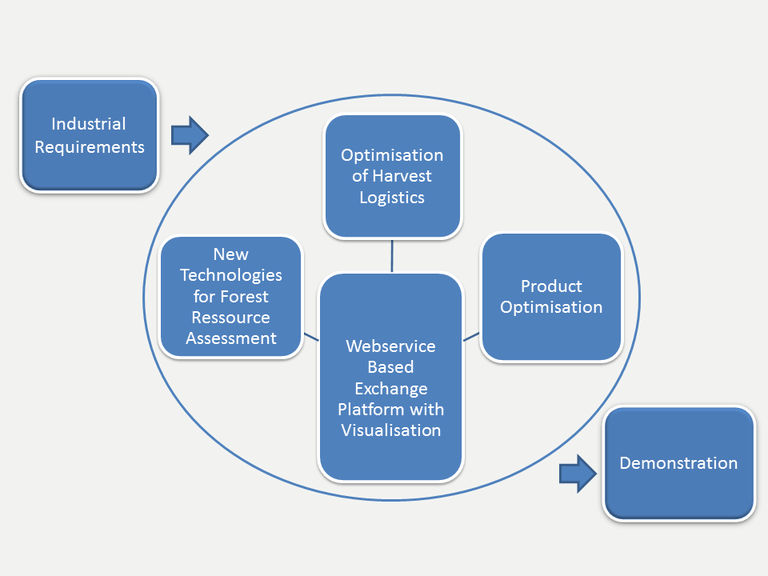

The work packages can be visualised as such:

The strategy was to combine the three research areas of new technologies for forest resource assessment (inventory), optimisation of harvest and logistics and product optimisation (saw mill) in a novel logistic system that makes use of IT components; the webservice based exchange platform. Basis for the research was first provided by the industrial requirements and the results were finally tested and evaluated in four Use Case demonstration.

Work parckage Objectives:

Industrial requirements (WP3000)

The main objective of this work package (WP 3000 Meeting Industrial Requirements) was to express and to describe the demands of main industrial sectors within the Wood Supply Chain (WSC) in terms of wood raw material qualities. It covers production of solid wood products (sawmills), pulp and paper (fibre) and bio-energies. It is often observed that industrials of the WSC must produce on any wood materials available and delivered, where wood raw material pushes the manufacturing of certain products. Combining industrial demand with new technologies such as remote sensing, which enable to identify wood properties early in the chain, opens the door for more efficient processes and material uses.

New technologies for forest resource assessment (WP4000)

In this work package (WP 4000 Integrated Forest Inventory Design for Optimised Quality and Quantity Assessment of Wood Resources) the aim was to develop an integrated forest inventory design for optimized quality and quantity assessment of wood resources. The main objective was to use remote sensing data from both aerial (ALS) and terrestrial (TLS) laser and optical technologies (multispectral and hyperspectral images) to obtain advanced quality and quantity information on wood resources measured in the forest with the novel technology. The specific research objectives were

- to develop and optimise ALS and TLS methods for assessment of wood quality and quantities at high spatial resolution and validate these methods, and

- to optimise the combination of different data sources, such as ALS, TLS, existing geo-spatial data, optical sensor data and field measurements, in description of tree and wood properties.

Optimisation of harvest and logistics (WP5000)

The first thing done in this work package (WP 5000 Novel Harvesting and Logistic Concepts for Integration of Forestry with Industry) was to develop a generic method to describe and measure different wood supply systems. According to that the special circumstances for small private forest owner’s situation in central Europe were described. Thereafter, the data needed to build a planning model was described; especially supply descriptions of forest stands via laser scanning and industrial demand. In addition, more flexible means to adapt the bucking processes in the cut to length harvesters were investigated. Finally, the work package ended with the development of a planning model to match industrial demand with forest supply efficiently using operational means i.e. harvest- and transport equipment and road network.

Product optimisation (WP6000)

There were three main objectives of this work package (WP 6000 Flexible and Customer Adapted Mill Production); (1) To collect data (e.g. scanning technology) to provide information for modelling the manufacturing processes (saw mill and secondary conversion) and further on to final products (sawn timber and value added components); (2) To create concepts for converting wood raw material into sawn timber and wooden components through radically more flexible manufacturing processes than in the current situation. (3) To integrate the forest optimisation models from WP 5000 into conversion models.

Webservice based exchange platform (WP7000)

The role of this work package (WP 7000 Communication Infrastructure for the Support of Increased Wood Supply Efficiency) in FlexWood was to deliver and implement an architecture to provide the IT infrastructure for collaboration of many forest related services. This collaboration is a key to the success of the FlexWood project as it allows a complete integrated model of the forest supply chain to be achieved. Only by bringing the various services together can there be a synergistic effect, to realise many new types of knowledge which can be determined before, during and after harvesting. The other important aspect of the architecture is the multitude of potential stakeholders in different locations capable of using the system. The architecture must therefore support multiple views of the operations and data from a wide variety of devices and only allow certain functions and results to be available to each stakeholder.

Demonstration (WP8000)

There were two tasks in this work package (WP 8000 Implementation and Demonstration of the FlexWood Concept); the first was to test the practical implementation of the FlexWood concept in different use cases in cooperation with forest industry partners in Europe, and thus demonstrate its relevance. Demonstrations were arranged in four European countries representing different forest types and ownership structures as well as different forest use practices: France, Germany, Sweden and Poland. The second task aimed to evaluate the FlexWood concept. More specifically, it was to assess the ability of new technologies (mainly LIDAR) and optimized planning systems to make the Wood Supply Chain more efficient at an acceptable cost. This evaluation was based on four demonstration sites where new technologies were implemented. Although these results may not be generalizable and will be specific to local situations, some recommendations for the implementation of new technologies according to the types of sites were made.